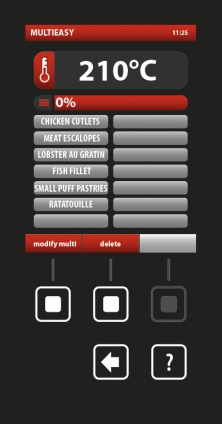

Level 2 Combi Oven

GBS Combistar FX202G2

FX Combistar Description:

- Multi-function combination oven with digital controls, LED display

- BOILERLESS TECHNOLOGY saves energy with no reduction in volume, saves servicing thru reduction of duplicity

- Built to save money and energy through the use of patented new technology

- ECO function - reduces water consumption during the cooking and washing processes.

- APM power management increases power supplied until the desired temperature in the cooking environment is reached

- AOC (patent pending) allows operation with "overpressure cooking

- AWC automatic control of the motor‘s rotation constantly assuring consistency of cook and colouring

- The RDC (patent pending) steam generator ensures a constant supply of steam throughout "steam" and "combination cooking" modes

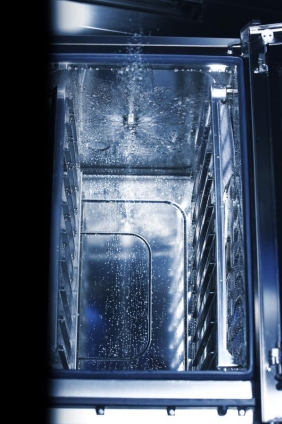

- Instantaneous steam generation within oven cavity

- Electronic self-diagnosis with malfunction alarms for key operating areas

- Semi automatic or fully automatic self cleaning ability

- High temperature steam (from overpressure) for Hi-Temp steaming

Product Features:

- Multi-Function Combi Oven with digital controls, LED display (7 segments).

- Convection from 50°F to 572°F (10°C to 300°C) and humidity % from 0 to 100 / Combination cooking from 86°F to 482°F (30°C to 250°C) and steam % from 10 to 90 / Steam from 86°F to 257°F (30°C to 125°C).

- Cooking modes: manual or programmable selection, 100 programs with 4 phases , standard 3 re-heating programs, 5 smoking, 4 Low Temperature and 1 Delta T.

- Pre-Setting for smoke with accessory SMOKERSTAR.

- ECO FUNCTION for the consumption reduction in cooking and washing.

- SEMI-AUTOMATIC WASHING PROGRAMS with double action sanitizing effect in the cooking chamber SC2.

- Data selection control knob, backlit touch sensitive keys.

- RDC steam generator with low management cost. Manual steam injection.

- Generating steam optimizer EVOS.

- Functions for the active control of: APM power (gas models), AOC management of the cooking chamber with overpressure, humidity control UR2, automatic fan reverse AWC, 3 fan speeds (1 intermittent), PTM temperature state, PLUS extra power (gas models).

- Alarm reset keys. Self-diagnosis with malfunction alarms. Continuous halogen chamber lighting. Automatic Cooling and Preheating.

- SINGLE-POINT TEMPERATURE CORE PROBE.

- Interface for HACCP data downloading on printer (optional).

- Pre-setting for remote control of power peaks.

- Start-up time selection.

Construction Features:

- Construction in stainless steel

- AISI 304 stainless steel polished cooking chamber, with AISI 316L (3/64 inch or 1,2 mm thk) top and bottom and rounded edges without joints

- Gas exchanges made of AISI310S and AISI316L stainless steel; electric exchanger made of Incoloy 800

- Cooking fan and steam generator in AISI 316L stainless steel

- Halogen chamber lighting

- Control panel protected by 7/32 inch (5 mm) of tempered glass

- Removable container racks

- Deflector panel between cooking chamber and exchanger/ fan opening on hinges for services and cleaning

- Door with intermediate stop positions at 90° and 130° and with double tempered glazing 15/64 inch (6 mm) with open-cavity and external low emissive glazing, internal removable glazing - rock wool

- Ceramic fibre thermal insulation (1-3/8” or 3,5 cm) with anti-radiation barrier

- Handle with double handgrip, easier opening also with hands full

- High-strength door gasket with double sealing line, in silicone

- Condensation collection and drain integrated tray

- All operating elements are located near the technical compartment on the left-hand and front side of the oven

- IPX5 protection degree

- Cooking chamber siphon drain to prevent back flow of liquids and smells and with T pipe for ventilated downstream installation